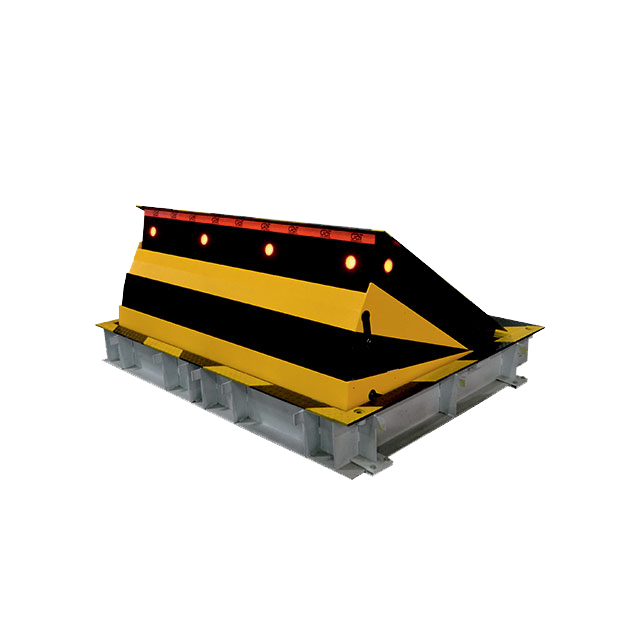

Anti-ram road blockers are an alternative solution that does not need a large installation depth, however, it provides the same level of security as bollards.

- Cyclope m30, m40, m50;

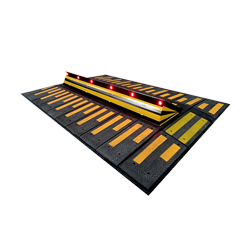

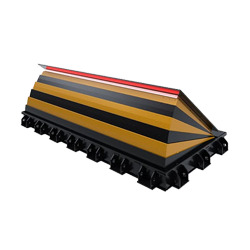

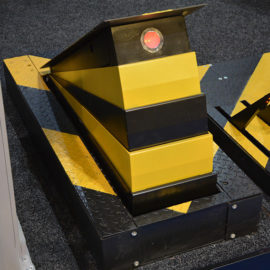

- Speedbump road blockers m30, m40, m50

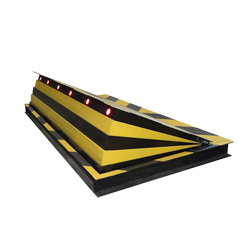

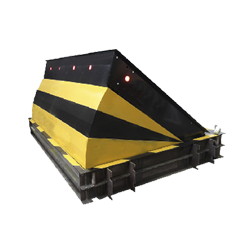

- Road blocker m30, m40, m50

Installation areas:

• Business (Office) Centers • Governmental Institutions • Financial Institutions • Military Bases • Hotels • Education Institutions • Sport Complexes • Nuclear Power Plants • Production sites (Industrial Plants) • Airport Premises • Commercial areas • Recreation areas

We are the only company that has anti-crash certificates for road blockers that do not need earthmoving and are installed on the surface.

General notes for Cyclope road blockers:

- High Security:

- Above the ground installation – attachable ramps are mandatory;

- Ground level installation -shallow mounted installation/foundation case is mandatory;

- Outside control box with PLC and Hydraulic unit;

- Blocking segment connected to control box with hydraulic hoses and connection cable;

- Range is classified by a blocking width: 2m, 3m, 4m;

- Blocking height: 495 mm;

- Power supply: 3 Phase 380 V

Citylight Cyclopes:

- Built-in hydraulic unit with outside PLC;

- Blocking segment connected to PLC with connection cable only;

- Shallow mounted installation/foundation case is mandatory;

- Power supply: 1 Phase 230 V

- General notes for Speedbumps road blockers:

High-security:

- Has optional above the ground and ground level installation types;

- Above the ground installation – shallow mounted installation / foundation case is mandatory;

- Outside control box with PLC and hydraulic unit;

- Blocking segment connected to control box with hydraulic hoses and connection cable;

- Range is classified by a blocking width: 2m, 3m, 4m;

- Blocking height: 495 mm;

- Power supply: 3 Phase 380 V.

Citylight:

- Has optional above the ground and ground level installation types;

- Above the ground installation – attachable ramps are mandatory;

- Ground level installation – shallow mounted installation/foundation case is mandatory;

- Built-in hydraulic unit with outside PLC;

- Blocking segment connected to PLC with connection cable only;

- Range is classified by a blocking width: 2 m, 3m, 4m;

- Blocking height: 350 mm;

- Power supply: 1 Phase 230 V.

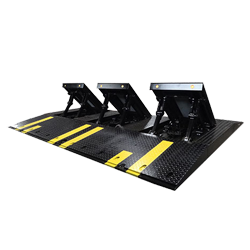

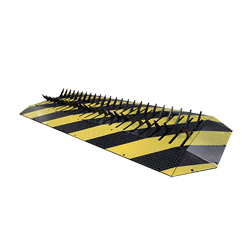

TIRE-KILLERS

- General notes for automatic tire-killers:

- Has optional above the ground and ground level installation types;

- Above the ground installation – attachable ramps are mandatory;

- Ground level installation – shallow mounted installation/foundation case is mandatory;

- Outside control box with PLC and hydraulic unit;

- Blocking segment connected to control box with hydraulic hoses and connection cable;

- Range is classified by a blocking width: 2m, 3m, 4m;

- Range is classified by heigh of spikes: 80 mm or 170 mm;

- Range is classified by spikes rising direction: one-directional or bi-directional;

- Power supply: 1 Phase 230 V.

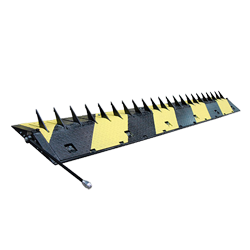

General notes for mechanical tire-killers:

- Electricity not required;

- Above the ground installation (ground level solution is optional);

- Range is classified by a blocking width: 2m, 3m, 4m;

- Range is classified by heigh of spikes: 80 mm or 170 mm;

- Three available operation modes: spikes down, spikes up and blocked; spikes up and one direction free.